Sugarcane Fiber

Meat Trays

Engineered with EVOH barrier film for up to 21 days of shelf life and exceptional leak protection, even under freezing conditions

Advanced EVOH High-Barrier Technology

Tested at -30°C, our trays maintain perfect seal integrity with zero air leakage, preserving color, flavor, and quality throughout the cold chain.

Oxygen Barrier

Days Of Freshness

Leakage Rate

Key Advantages

Why Choose MIDA Sugarcane Meat Trays

Advanced packaging technology that delivers unmatched freshness preservation for the protein industry.

21-Day Proven Freshness

Our trays preserve meat’s natural color, flavor, and texture for extended shelf life, reducing waste and maintaining premium product quality.

Advanced Oxygen Barrier Protection

The EVOH film delivers complete oxygen blockage, preventing microbial growth and discoloration.

Tested for Extreme Conditions

Proven performance at -30°C with zero leakage, maintaining seal integrity through freezing, transport, and thawing.

Eco-Friendly by Nature

Crafted from 100% renewable sugarcane fiber, our trays are fully compostable and align with sustainable packaging standards across global markets.

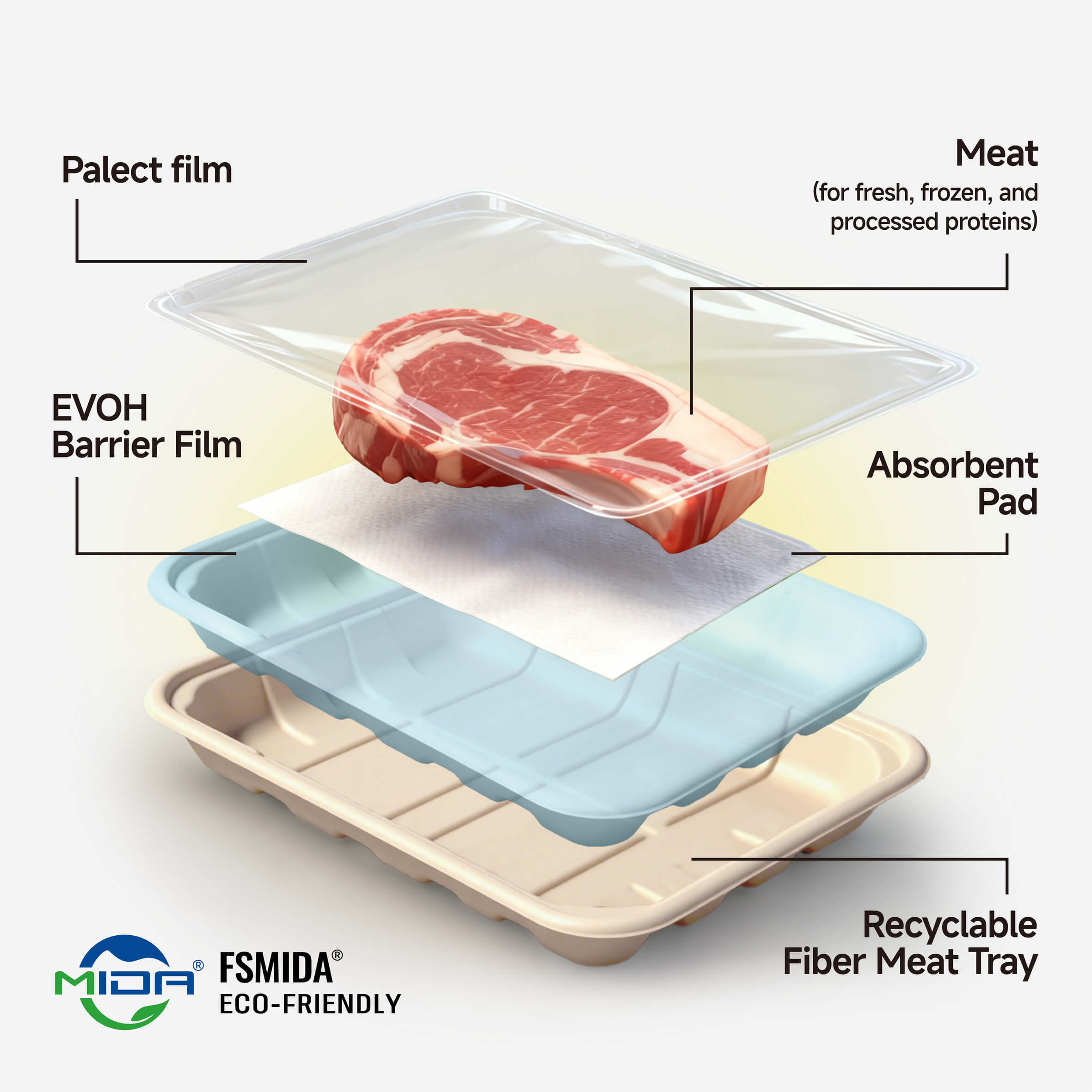

Technical Advantages

Outstanding Gas Barrier Performance

Our meat trays combine renewable sugarcane fiber with EVOH high-barrier film, delivering advanced protection and sustainability for the protein packaging industry.

EVOH Barrier Film

Effectively blocks oxygen transmission to preserve color, flavor, and nutritional quality.

Sugarcane Fiber Base

100% plant-derived molded pulp with excellent rigidity and environmental benefits.

Low-Temperature Reliability

Proven performance under -30°C, maintaining complete seal integrity without air leakage.

Certified for Global Standards

At MIDA, our commitment to quality and environmental

responsibility is backed by globally recognized certifications.

Applications

Designed for Protein Applications

Our high-barrier meat trays are engineered for fresh, frozen, and processed proteins.

Tailored Solutions for the Protein Industry

Target Industries

Meat & Poultry Processors

Providing dependable packaging solutions engineered for consistent product quality, and streamlined production across large-scale processing facilities.

Learn more

Supermarkets & Retailers

Delivering packaging that minimizes food waste, and extends product shelf life — supporting improved profitability.

Learn more

Food Service Distributors

Ensuring reliable packaging performance during extended transport and fluctuating cold-chain conditions, maintaining product safety and freshness.

Learn more

Sustainable Innovation for Meat Packaging

At MIDA, environmental performance is built into every stage of our packaging development. Our sugarcane fiber meat trays are designed for professional food applications that demand both freshness protection and sustainability compliance.

Core Sustainable Features

Molded tray from renewable sugarcane fiber sources

Compostable pulp base after film separation

Designed for efficient recycling and responsible disposal

High-barrier EVOH film ensuring product integrity and extended shelf life

Optimized manufacturing process with 98% finished product yield

Ready to Revolutionize Your

Packaging?

Join industry leaders who trust our high-barrier molded pulp trays for superior freshness preservation. Contact us today for samples and technical specifications.

Yes. We provide full-service customization, including product design, mould development, logo printing, and packaging. OEM and ODM solutions are available to meet market needs.

Yes. We offer free samples. For custom items, samples are available after confirming design specifications and mould requirements.

Generally, Mass production time will take 5–25 working days. For custom moulded products, production lead time is 15–30 days, depending on tooling complexity and order volume. We support urgent requests.

Our products are certified by international standards, including BPI, OK Compost, FSC, FDA, BRC, and are produced under ISO9001 quality management systems. All materials are sugarcane bagasse and compliant with global food safety and compostability requirements.

Absolutely. Our packaging solutions are designed for export, comply with major environmental regulations, and are optimized for retail, foodservice, and supply chain integration across international markets.

Thank you for considering MIDA as your eco packaging partner. We’re looking forward to learning more about your project needs.

Foshan MIDA Eco-friendly Product Co., Ltd., focusing on development and production of biodegradable and compostable disposable pulp molding tableware products.

Room 3705, Tower 1, China Merchants Land Center,No. 26 Guilan North Road, Guicheng, Nanhai District,Foshan, Guangdong, China

MIDA Tableware

Typically replies within minutes

Any questions related to our biodegradable tableware?

WhatsApp Us

🟢 Online | Privacy policy

WhatsApp us